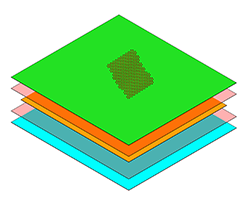

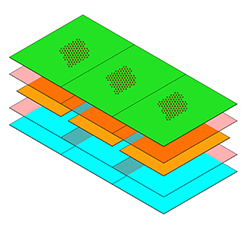

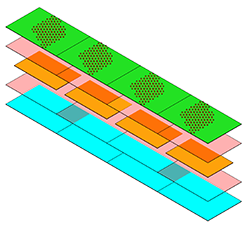

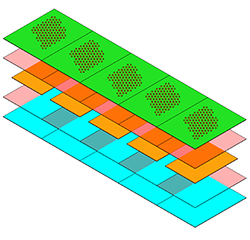

Meat Pad/Lamination

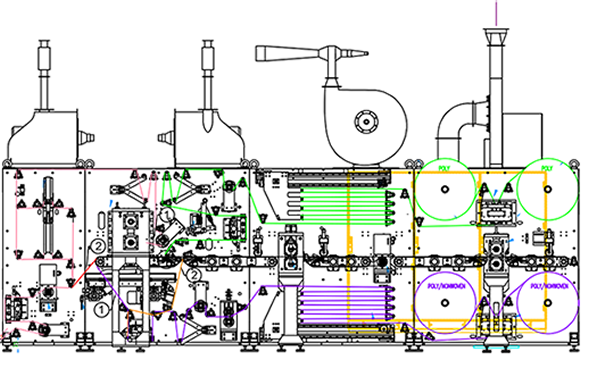

MP300 - Full Servo

Speed: 300 ml/min

SANIMAC has developed an absorbent Pad Making Technology for absorbent products such as lamination, core, meat Pads, fluffless underpads, etc...

Focused on finished product cost and quality, as well as equipment flexibility, we have developed

and successfully run a new type of machine, which has a compact design and thus can be run in small and efficient facilities with minimum personnel required, meaning low labor costs.

The machine has a superior price/performance ratio, is very flexible and provides first class products at very low cost.

The extreme flexibility of the machine allows customers to enter the market by being able to produce a full range of products such as Lamination, Underpads for hospitals, Underpads for dogs, Meat Pads, Fruit Pads, Fish pads, Breast Pads (Nursing pads) and similar applications with very little changeover requirements.

The advantages of this concept are:

- Very low implementation and start up costs.

- Easy adaptation to local raw material and final product specifications.

- High efficiency and minimum waste.

- Raw materials and final product flexibility.

- Low energy consumption, very small utilities and little space are required.

- Most simple cleaning, operation and maintenance.

- Quick, reliable and low risk multiplication.

- Low operational requirements.

The machine is capable of realizing the most up-to-date concept of absorbent pad products in a great variety of sizes, materials and formats used in the industry (up to 600mm width and 1000mm long).

When it comes to packaging, the products can be counted and separated in a fully automatic process, and then be packed by hand or in a fully automatic system.

The products can be as well rewinded into rolls.