Cellulose Web/Airlaid Machine

Cellulose Web/Airlaid Machine

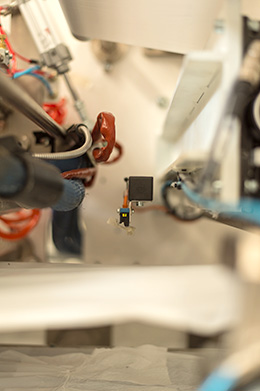

SANIMAC has developed an AirLaid Technology for the manufacturing of a fiber web and similar web products, focused on finished product cost and quality, as well as equipment flexibility.

Sanimac stands out for the design and construction of machinery to be used in the most efficient environmentally friendly production techniques. Saving costs, natural resources and re-using of waste is the obsession of our engineers and designers. Our airlaid production systems are set for a wide range of everyday use products: sustainable free from plastics, no water waste and food grade standard using natural, cellulose and waste derived and biodegradable primary materials.

We have developed and successfully run a new type of machine, which has a compact design and thus can be run in small and efficient facilities with minimum personnel required, meaning low labor costs.

The machine has a superior price/performance relation, is very flexible and provides first class products at very low manufacturing cost.

The extreme flexibility of the machine allows customers to enter the market by being able to produce his full range of products such as Cellulose conteners and similar objects or applications with very little changeover requirements.

The advantages of this concept are:

- Very low implementation and start up costs.

- Easy adaptation to local raw material and final product specifications.

- High efficiency and minimum waste.

- Raw materials and final product flexibility.

- Low energy consumption, very small utilities and little space are required.

- Most simple cleaning, operation and maintenance.

- Low operational requirements.

The machine is capable of realizing the most up-to-date concept of fiber web in a great variety of sizes, materials and formats used in the industry.

When it comes to packaging, the products can be handled in a fully automatic process, and then be packed by hand or in a fully automatic system.

GENERAL DESIGN AND TECHNOLOGY HIGHLIGHTS

The advanced simplified engineering design stands for an extremely simple machine that produces first-class quality products at very high efficiency and extremely low waste rates.

- A state-of-the-art forming system allows a reduction in key material requirements and to produce products with better performance.

- The compact design allows fast, economic and trouble free installation of the equipment with the lowest start-up time known in the sector. Small footprint (machine dimensions) requires very little space.

- Simple design, together with a user-friendly process visualization system, without requiring specialized skills to operate the machine.

- High flexibility: easy and economic conversion of machine to produce different products, with low investment and low changeover time.